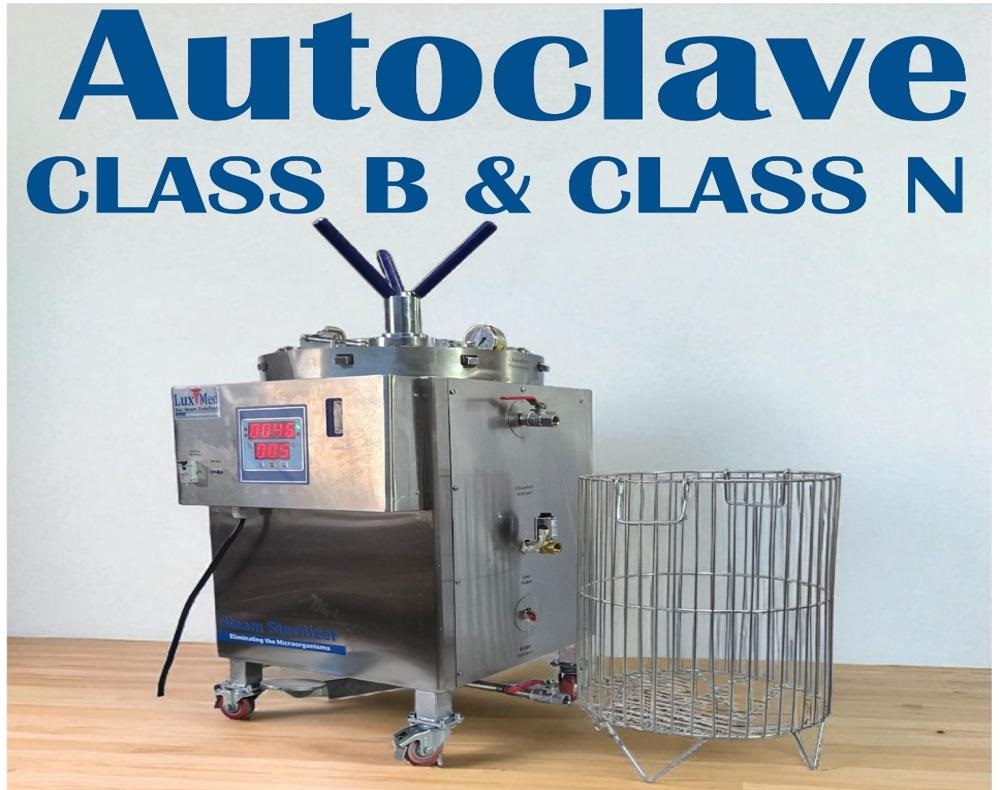

LuxMed Single Door Cylindrical Steam Sterilizer

Price 650000.0 INR/ Piece

LuxMed Single Door Cylindrical Steam Sterilizer Specification

- Usage

- Industrial

- Color

- Silver

- Product Type

- Cylindrical Steam Sterilizer

- Voltage

- 220-240 Volt (v)

- Operate Method

- Semi Automatic

- Material

- SS

LuxMed Single Door Cylindrical Steam Sterilizer Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- at ambala

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 1 Week

- Sample Available

- No

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- wooden packaging

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- CE, ISO and MSME Certified

About LuxMed Single Door Cylindrical Steam Sterilizer

LuxMed -3M Hospital CSSD Equipment CSSD stands for Central Sterile Supply Department, which is a crucial component of healthcare facilities responsible for cleaning, sterilizing, and distributing medical equipment and instruments. CSSD equipment plays a vital role in maintaining the safety and sterility of medical instruments and ensuring patient well-being. LuxMed Provides different choices for CSSD equipment such as.

1. ETO Sterilizer

2. Plasma Sterilizer.

3. Pass Box Static and Dynamic.

4. Stainless Steel (SS304) Table & Trolley.

5. Instrument Drying Cabinet.

6. Washer-Disinfector.

7. Ultrasonic Cleaner.

8. Washing Station Double Sink.

9. Sterilization Wraps and Pouches.

10. Sterilization Containers.

11. Cleaning Supplies.

Efficient Industrial Sterilization

The Single Door Cylindrical Steam Sterilizer is engineered for heavy-duty industrial use, providing consistent and reliable sterilization. Its semi-automatic operation allows for precise control, while the sturdy stainless steel construction ensures durability in rigorous industrial environments.

Robust Stainless Steel Build

Built entirely from high-grade stainless steel, this sterilizer is resistant to corrosion and designed for longevity. Its cylindrical design ensures uniform steam distribution, resulting in effective sterilization cycles every time.

FAQs of Single Door Cylindrical Steam Sterilizer:

Q: How does the single door cylindrical steam sterilizer operate?

A: This sterilizer features a semi-automatic control system, allowing users to manage key sterilization functions manually while automating crucial processes for safety and efficiency. Just load the items, set the required parameters, and let the sterilizer handle the rest.Q: What industrial applications is this steam sterilizer suitable for?

A: It is ideal for any industrial setting where sterilization of instruments, components, or lab materials is required, such as in pharmaceuticals, research laboratories, food processing, and manufacturing facilities.Q: When should I use a steam sterilizer over other sterilization methods?

A: Steam sterilization is preferred when thorough and rapid sterilization of heat- and moisture-resistant items is necessary. It is especially effective for metal instruments, glassware, and certain types of industrial tools.Q: Where can this sterilizer be installed within an industrial facility?

A: The unit is compact yet robust, making it suitable for installation in dedicated sterilization rooms, laboratories, or production areas with access to a standard 220-240 Volt power supply.Q: What is the process for using the semi-automatic sterilizer?

A: Place items inside the chamber, close the single door securely, set the sterilization settings, and initiate the cycle. The device will automatically maintain temperature and pressure, with manual or automatic signals to indicate cycle completion.Q: How does using this sterilizer benefit my industrial operation?

A: It delivers consistent, high-level sterilization, reducing the risk of contamination and ensuring quality control in production processes. Durable construction and semi-automatic operation also help to optimize workflow and minimize downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hospital CSSD Equipment Category

LuxMed Flyer Autoclave Type -B

Price 210000.0 INR / Roll

Minimum Order Quantity : 1 Number

Material : Steel

LuxMed Steam Sterilizer Cylindrical Vertical

Price 250000.0 INR / Piece

Minimum Order Quantity : 1 Number

Material : Stainless Steel

LuxMed Multi Device Charging Station

Price 64900.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Usage : Industrial

Product Type : Multi Device Charging Station

Voltage : 220 Volt (v)

LuxMed Cylindrical Steam Sterilizer

Price 800000.0 INR / Piece

Minimum Order Quantity : 1 Number

Material : SS

Usage : Industrial

Product Type : Cylindrical Steam Sterilizer

Voltage : 220240 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS